The #1 Choice in the Rubber Industry for

Quality, Customization,and Quick Lead Times

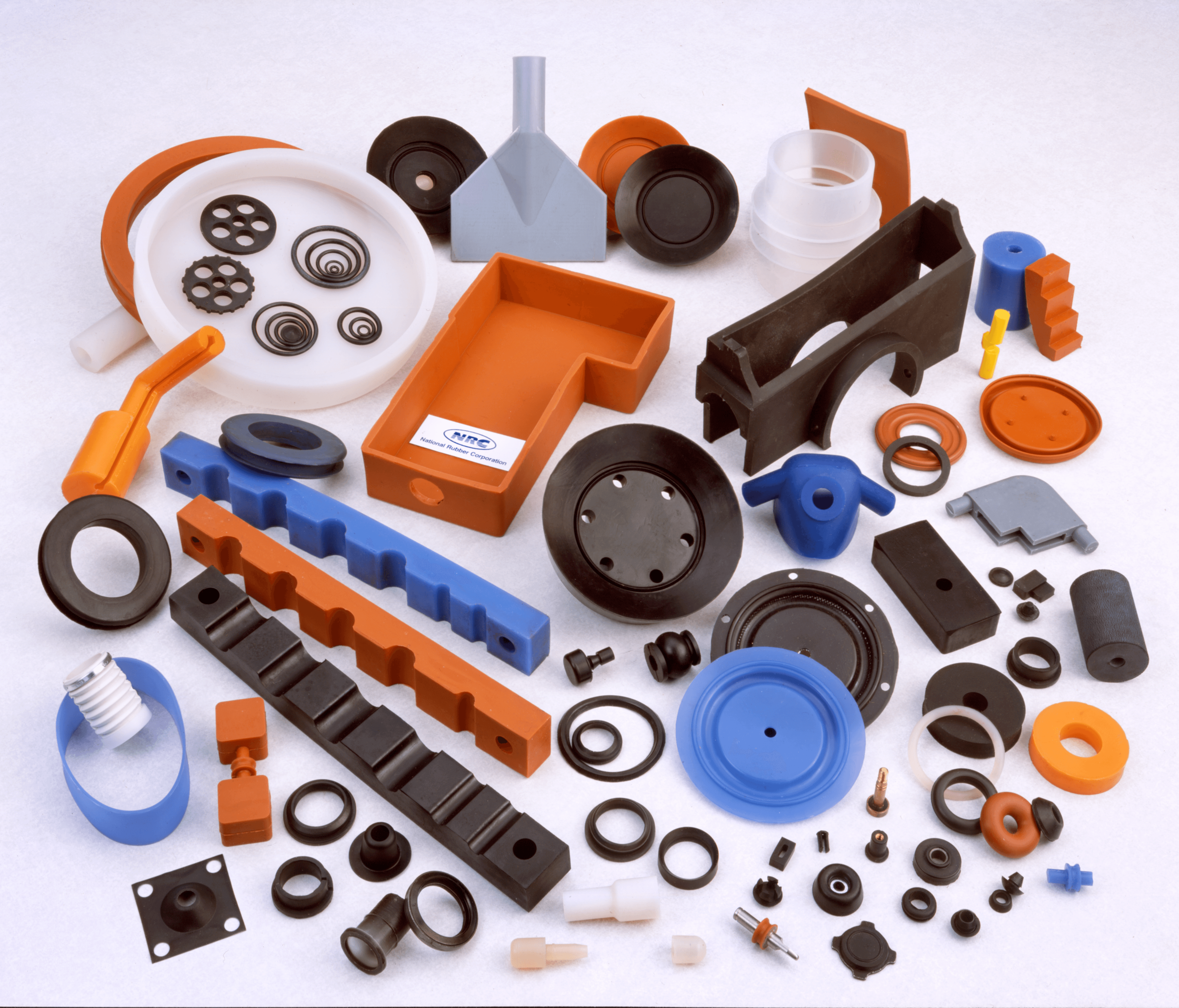

Experts in extruded rubber products, custom or standard shapes. You imagine it - we can extrude it. We also offer custom molding, mixing, die cutting and more. For all your project needs, submit a quote and let's get started today.

Browse the full catalog here to see all products or learn about our solutions offered below:

Rubber Manufacturing Solutions Overview

We specialize in rubber extrusion — from standard profiles to complex custom shapes — engineered to tight tolerances and repeatable quality. We also offer custom molding, die cutting, secondary fabrication, and compound mixing to support full lifecycle production.

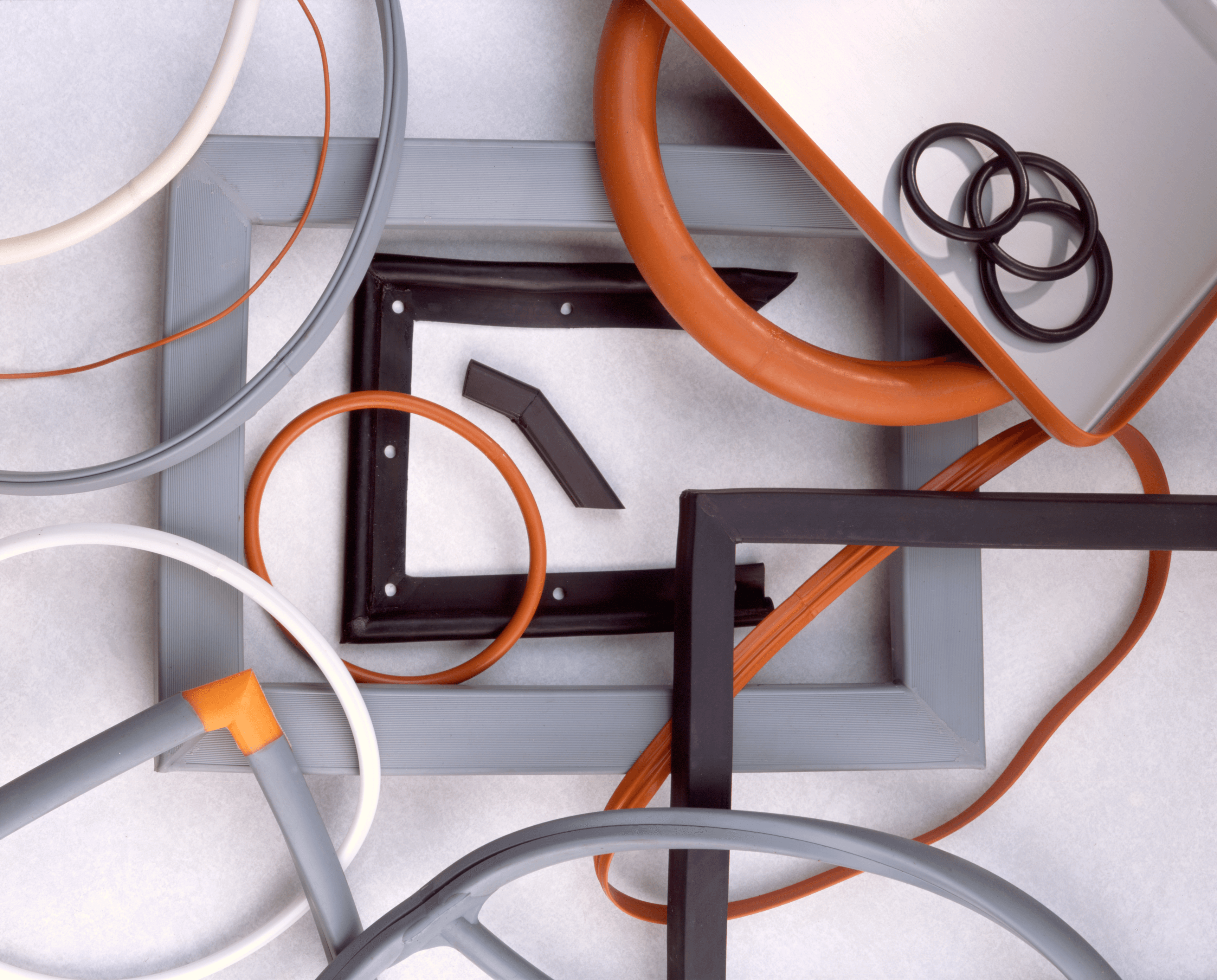

Custom Extrusion

Sophisticated control systems maintaining close tolerances for seals, gaskets, tubing, weather stripping, and insulation.

Custom Molding

Compression, transfer, and injection molding with natural and synthetic compounds including EPDM, Silicone, Nitrile, and more.

Die Cutting

High precision cutting of unique sheets from EPDM, FKM, Nitrile, Silicone and other materials to exact specifications.

Secondary Fabrication

In-house capabilities including corner molding, gasket fabrication, punching, precision cutting, and T-joint fabrication.

Custom Mixing

Variable speed, 50 horsepower mixers with high horsepower mills ensuring total consistency from batch to batch.

Spiral Wound Gaskets

Precision-engineered gaskets for high temperature and pressure applications with excellent resilience.

Why Choose National Rubber Corporation?

We combine technical expertise, quality materials, and advanced manufacturing to deliver superior rubber products.

Quality Assurance

Rigorous testing and quality control processes ensure our products meet the highest standards.

Custom Engineering

Our engineering team works with you to design rubber solutions for your specific applications.

Rapid Prototyping

Quick turnaround on prototypes to accelerate your product development cycle.

Technical Support

Expert technical assistance throughout the design, production, and implementation process.

Advanced Manufacturing

State-of-the-art equipment and processes for precision manufacturing.

Industry Certifications

Compliant with industry standards and certifications for quality and reliability.

Industries We Serve

Our rubber solutions are trusted across diverse industries requiring precision, durability, and performance. Click an icon to learn more.

About National Rubber Corporation

National Rubber Corporation is a U.S. manufacturer of custom rubber components, sealing solutions, and engineered elastomer products. We combine extrusion, molding, die cutting, and secondary fabrication under one roof to deliver consistent quality and tight tolerances. Our team supports projects from design-for-manufacture through repeat production, serving demanding applications across aerospace, automotive, appliance, electronics, transportation, construction, chemical processing, healthcare, and food & dairy. Materials include EPDM, Nitrile (NBR), Neoprene, Silicone (including FDA and high-temp grades), Fluoroelastomers, and specialty compounds matched to environmental, thermal, and regulatory requirements.

We help engineers reduce leakage, vibration, and noise; improve weather resistance; and enhance safety and longevity of assemblies. Typical deliverables include U- and C-channels, edge trim, grommets, O-rings and cord, sponge profiles, bumper stops, and precision die-cut gaskets. Request a quote to validate dimensions, durometer, and performance targets for your application.

Our process begins with application discovery and material selection, weighing tradeoffs in compression set, media compatibility, temperature range, abrasion, and cost. We then review profile geometry for manufacturability and consistent sealing force, produce rapid samples where needed, and finalize tooling for repeatable production. Incoming materials and finished goods are inspected against documented specs with lot traceability.

For OEM programs, we align on inspection plans, PPAP documentation, packaging, labeling, and replenishment strategies. Our in-house secondary operations cut lead time and reduce handling, while our team coordinates testing for specialized certifications or customer-specific standards. The result is a dependable supply of components that fit, seal, and last.

Ready to Discuss Your Rubber Manufacturing Needs?

Our team of experts is ready to help you find the perfect rubber solution for your application. Contact us today for a consultation or quote.

If you already know exactly what products or rubber solutions you want, please select items from our catalog directly and submit a quote when done.

You can also call us at:

(412) 831-6100Or visit our office:

367 Morganza RoadCanonsburg, PA 15317